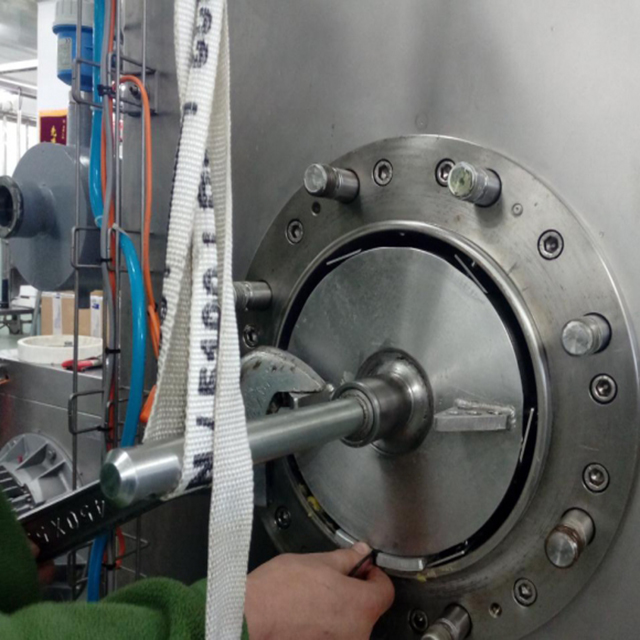

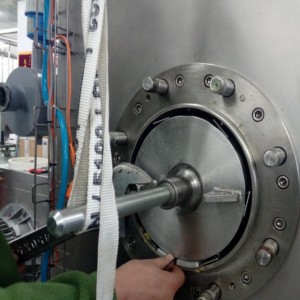

Votator-SSHEs Service, maintenance, repair, renovation, optimization,spare parts, extended warranty

Work scope

There are many dairy products and food equipment in the world running on the ground, and there are many second-hand dairy processing machines available for sale. For imported machines used for margarine making (butter), such as edible margarine, shortening and equipment for baking margarine (ghee), we can provide maintenance and modification of the equipment. Through the skillful craftsman, of , these machines can include scraped surface heat exchangers, votator machine, margarine making machine, margarine plant, shortening plant, quenchers, kneaders, refrigerators, margarine machines.

We have extended the life cycle of the machine to avoid waste. The quality and quality of our repaired margarine equipment has been confirmed many times in Denmark, Germany, the United States, the Netherlands, the United Kingdom, Sweden and other machines. We have given these margarine equipment, scraper type with fast OEM capabilities and professional services The second life of heat exchanger machines. These machines have been repaired, refurbished and remodeled by us, and can be easily extended after a thorough overhaul.

Retrofit maintenance

Our maintenance retrofit margarine equipment can cover the following most common scraped surface heat exchanger manufacturers:

Gerstenberg Agger (Denmark) is now SPX,

Schröder (Germany) is now SPX,

Cherry Burrell (USA) is now SPX,

Votator machine-Scraped surface heat exchanger (USA) is now SPX,

Chemteck (UK) is now TMCI Padovan, Chemetator-Scraped surface heat exchanger-Scraped surface heat exchanger-Votator

Contherm-Scraped surface heat exchanger (Sweden) is now Alfa Laval, Tetra Pak

Terlotherm (Netherlands) is now ProXES Group,

APV Ampere (USA) is now SPX,

MBS (Italy) is now Hercules.

HRS R series scraper heat exchanger of HRS-Heatexchanger (UK)

Ronothor series scraper heat exchanger of RONO (Germany)

Overhauling

1. Strip the frame, sandblast and spray steel parts

2. Surveying and remanufacturing damaged spare parts

3. Replace all wearing parts, including bearings, bushings and gaskets

4. Replace damaged or worn or aged or unreasonable parts

5. Arrange the updated machine for trial production

After our repair and reconstruction of the equipment, They can gain our company's 12-month warranty service period, and can provide 5 years or longer wearing parts supply warranty.

In addition to routine maintenance, we can replace imported margarine equipment with localized parts, such as honing, chrome plating, grinding or completely manufacturing completely new heat transfer cylinders (inner Tube, (Crystal tube); replace the sliding sleeve, wear ring; in addition, the scraper and mechanical seal can also be updated with Chinese accessories.